PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

Angular contact bearing balls (type 70000 AC) with α=25°, are inseparable and can only bear the axial force of one side, and the shoulder heights on both sides of the inner and outer rings are different, so more steel balls can be loaded to improve the bearing capacity. Mainly used in a wide range of industries such as automobiles, electrical equipment, machine tools, and aircraft.

VIEW MORE +

Angular contact bearing balls (type 70000 C) with α=15° can bear unidirectional axial load. When bearing pure radial load, bearings must be installed and used in pairs, because the action line of rolling element load and the action line of radial load are not in the same plane, resulting in internal separation force.

VIEW MORE +

Angular contact bearing balls with α=40° (70000 B type), can accommodate axial loads in one direction only. This type of bearing is typically adjusted against a second bearing. Their bearing rings have an upper and a lower shoulder and are non- separable. Mainly used in a wide range of industries such as automobiles, electrical equipment, machine tools, and aircraft.

VIEW MORE +

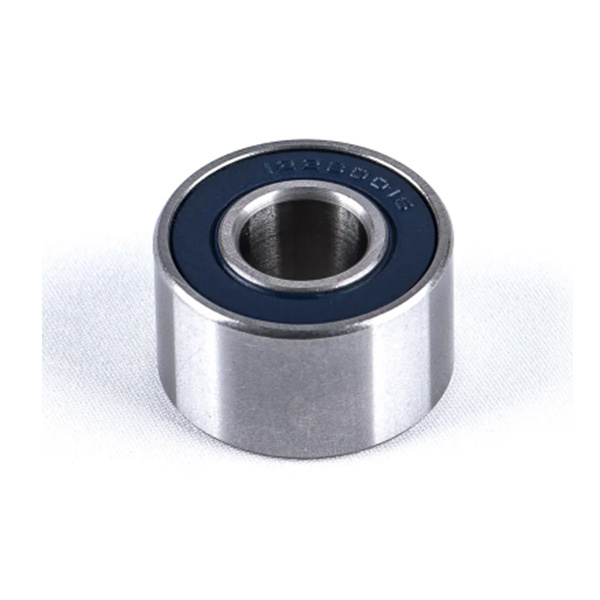

Single row angular contact ball bearings consist of an outer ring, an inner ring, a row of steel balls and a cage. This type of bearing can bear radial load and axial load at the same time, and can also bear pure axial load, and can work at high speed. Single row angular contact ball bearings can only withstand axial loads in one direction.

The "BEP" suffix is a nylon retainer, and the "BECBM" suffix is a copper retainer.

VIEW MORE +

29° contact angle

"D" indicates a duplex ground half pair matched with an identical half pair and is followed by an additional suffix letter to describe the type of duplex.

VIEW MORE +

Double row angular contact ball bearings correspond, in their design and operation, to a pair of single row angular contact ball bearings in a back-to-back arrangement, while requiring less axial space. They can operate at high speeds and are more suitable than deep groove ball bearings for supporting large axial forces in both directions.

VIEW MORE +